SELECT THE WORDS & LEVEL

Technology has advanced throughout history, transforming and revolutionizing many industries. The aluminum extrusion market is no exception; companies are consistently discovering new methods for creating innovative parts that are made from lightweight, durable aluminum.

In this blog post, we’ll examine some of the latest forms of technological advancement in the field of aluminum extrusion and discuss how these advances will positively affect businesses within this sector.

From increased efficiency and faster fabrication times to improved accuracy and quality control, modern advancements in business technology have had a tremendous impact on the production capabilities of those who produce custom-designed aluminum extrusions. Read on to learn more about what our current technologies can offer an expanding industry!

Exploring the Benefits of Working with an Aluminum Extrusion Company

The benefits of working with an aluminum extrusion companies are numerous and can greatly impact the success of your project. One of the most significant advantages is the ability to create complex shapes and designs with precision and accuracy.

This level of customization can help streamline your manufacturing process, increase efficiency, and reduce costs. Furthermore, aluminum extrusions are known for their high strength-to-weight ratio, corrosion-resistant properties, and eco-friendliness.

Overall, partnering with an aluminum extrusion company can take your project to the next level and deliver exceptional results.

Highlighting Recent Technological Advances in Aluminum Extrusion

Aluminum extrusion technology has come a long way in recent years, thanks to some truly groundbreaking advances. These advancements have opened up a world of possibilities for this versatile material, from the development of new alloy compositions to cutting-edge manufacturing techniques.

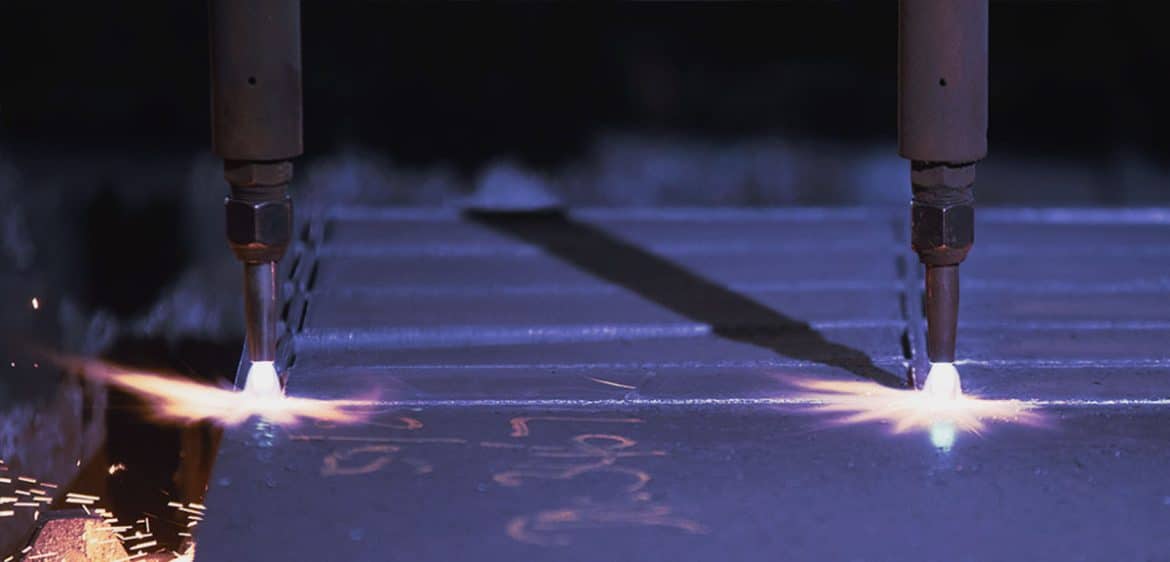

Some of the most exciting innovations include hot extrusion, which allows for more precise control over the metal’s properties, and friction stir welding, a method that produces incredibly strong joints without the need for additional materials.

Additionally, 3D printing technology is now being used to create intricate extrusion dies with unprecedented precision. All of these advancements are helping to drive the use of aluminum extrusion in an ever-expanding range of industries, from aerospace to consumer electronics.

With so much innovation on the horizon, it’s an exciting time to be a part of the aluminum extrusion community.

Examining the Role of Automation and Robotics in Aluminum Extrusions

In our constantly evolving world, automation and robotics have become crucial to the advancement of many industries.

These technologies have greatly impacted the aluminum extrusion industry, offering a range of benefits from improved efficiency to increased precision in the manufacturing process. With automation, tasks that were once manual can now be completed faster and more streamlined.

On the other hand, robots offer a level of accuracy that is difficult to achieve with human hands alone. When working together, these technologies can seamlessly bring complex designs to life and easily create customized extrusions.

As the demand for high-quality and cost-effective solutions increases, we can expect to see even more innovation in automation and robotics for aluminum extrusions.

Learning How CAD Software Enhances Aluminum Extrusion Design

Aluminum extrusion design is becoming increasingly popular as more and more industries realize the benefits of this versatile material. However, the design process can be complex and time-consuming.

That’s why learning how to use CAD software can be a game-changer. It allows you to easily create precise models and speeds up the design process.

With CAD software, you can make changes to your design quickly, experiment with different shapes and dimensions, and produce 3D models to better understand what your final product will look like.

If you want to improve your aluminum extrusion design skills, CAD software is worth investing in!

Understanding the Role of Quality Control in Producing Quality Extrusions

Quality control is an integral part of the manufacturing process and plays a vital role in producing high-quality extrusions. The goal of quality control is to minimize defects and ensure that each product meets the desired specifications.

Quality control is not limited to just the final product but also involves monitoring and maintaining the quality of the raw materials, equipment, and manufacturing processes. Ultimately, the success of quality control lies in the hands of skilled technicians and engineers, who are tasked with identifying and resolving any issues that may arise.

Without their expertise and attention to detail, achieving consistent and reliable products would be an uphill battle. Overall, quality control is a crucial aspect of extrusion manufacturing that ensures that the end product meets both the manufacturer’s and their customers’ expectations.

In conclusion, the aluminum extrusion process has come a long way and provides many opportunities for businesses and projects in the industry. By working with experienced aluminum extrusion companies, you can take advantage of recent developments such as automation, robotics, and CAD software.

With all these advancements embraced within the aluminum extrusion industry today, it’s no wonder why so many businesses rely on this technology for their critical operations.